How to measure the process technology of a product? This requires understanding the manufacturer of the product in question! For cable trays, Fengtu Cabling Cable Tray Manufacturer is highly favored in the Shanghai market for its excellent quality and better service! In Fengtu’s corporate culture, “quality” and “service” are eternal central ideas, everything for customers, everything for the brand, and everything for the internationalization of the industry!

Sincere quality, efficiency first! Efficiency is essential when quality is guaranteed! Efficiency is the spiritual state of a company, not just a display of its corporate style! Scientific management, quality service! The manifestation of quality is not solely focused on product quality, and the same applies to service. We must pay attention to quality service! In terms of technology, let’s discuss the issues related to technology here. Here, we focus on the relevant issues that need to be paid attention to before installation that have customer comments. Customer friends may not be familiar with the precautions that need to be taken before installing cable trays, as follows:

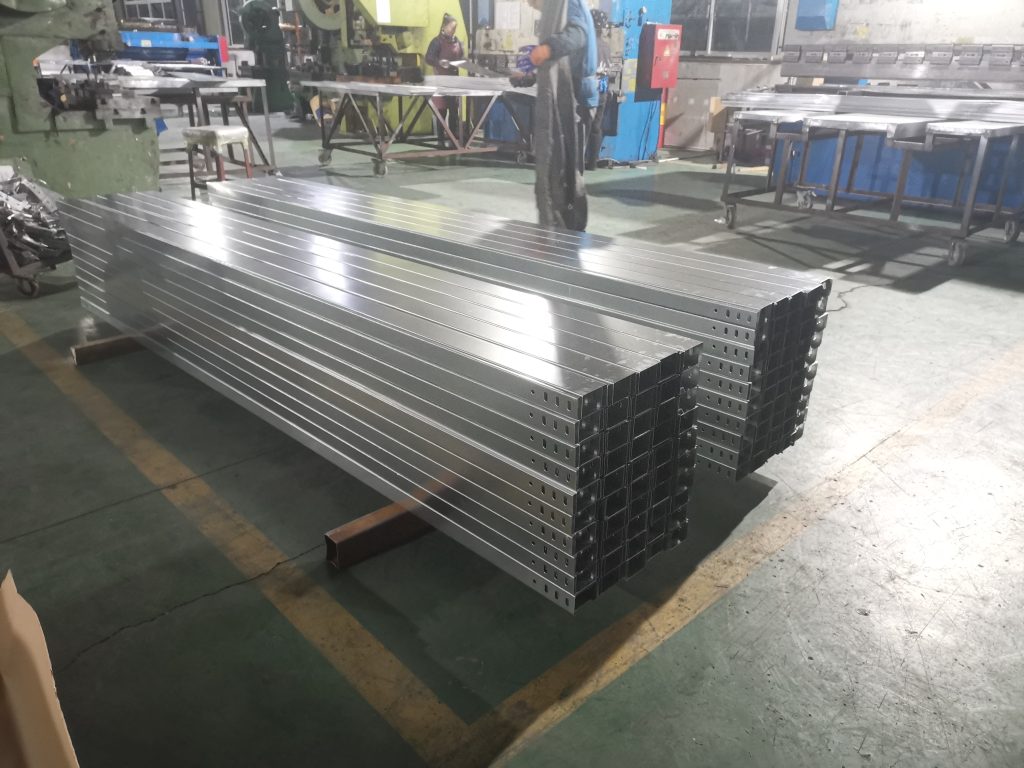

A. For special shaped cable trays, the dimensions measured on site will be handed over to the material supplier for production based on the dimensions, reducing on-site processing. The material, model, thickness, and accessories of the bridge meet the design requirements.

B. Before installing the bridge, it is necessary to coordinate with various professions to avoid conflicts with large-diameter fire pipes, sprinkler pipes, hot and cold water pipes, drainage pipes, air conditioning and exhaust equipment.

C. Lift the bridge to the designated position and fix it with bolts to the bracket. Carefully check the dimensions at the turning point. The bridge should be consistent with the slope of the building. For the bridge on the curved wall of the building, its arc should be consistent with the building. The bridge frames are connected to each other with connecting plates, and the connecting bolts use semi-circular head bolts, with the semi-circular head on the inside of the bridge frame. The gaps between the cable trays must meet the design requirements to ensure that the cable trays of a system are connected as a whole.

D. The bridge frame crossing the deformation joint of the building should be treated with expansion joint according to the enterprise standard “Installation Process of Steel Cable Bridge”. When the straight section of the steel bridge frame exceeds 30m, a thermal expansion and contraction compensation device should be installed. E. The installation of cable trays should be horizontal and vertical, neat and beautiful, with consistent distance and firm connection. The horizontal deviation within the same horizontal plane should not exceed 5mm/m, and the straightness deviation should not exceed 5mm/m.

Comments (0)